for special developements

CUSTOM PORTFOLIO

The process of customized products of Amfora Packaging includes different stages:

Product Ideation

From an idea that our client has, we can present product design alternatives that are viable for manufacturing in plastic manufacturing processes.

Conceptualization and Product Design

We have the ability to offer our customers different shapes, resins and capacities. At this stage we can present designs, renders, 3D prototypes.

Mold Making

Once the designs are approved, we start the process of construction and manufacturing of molds. We have a mold workshop, where, on average, more than 100 molds are developed each year. We offer short development times of 6 weeks.

Pilot Test and Samples

When the mold is finished, we proceed with the tests of the same, where we make technical adjustments in case they are necessary. We also make tests on customer filling lines and validations according to approved product plans.

Final Production

With the approval of the client, we give the authorization for the production of an industrial batch, coordinating the final delivery with the logistics area.

Sucess Stories

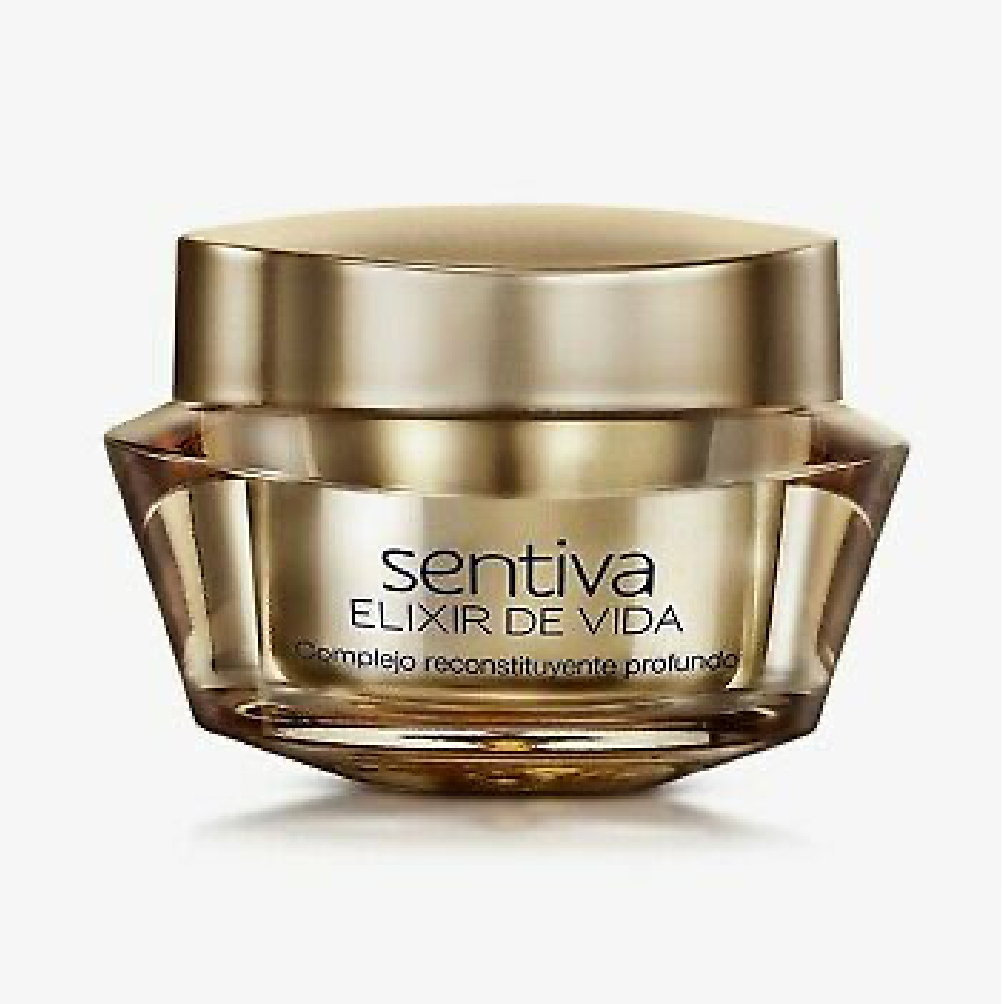

Metallic Jars for Tricorbraun in the United States

The challenge: Reduce logistics costs and delivery times.

We developed a line of jars with a metallic finish, attractive, functional and competitive in price, with excellent delivery times for one of the most important clients in the United States, TricorBraun.

More than 200 jars per year have been shipped from Bogotá to four different locations in the United States.

The high quality of the product and the reduced costs have made Intecplast the main supplier of these products.

Metallic Jars for Tricorbraun in the United States

The challenge: Reduce logistics costs and delivery times.

We developed a line of jars with a metallic finish, attractive, functional and competitive in price, with excellent delivery times for one of the most important clients in the United States, TricorBraun.

More than 200 jars per year have been shipped from Bogotá to four different locations in the United States.

The high quality of the product and the reduced costs have made Intecplast the main supplier of these products.

The beginning of our relationship with Tricorbraun was a development of an award-winning extrusion blown metallized (EBM) HDPE bottle for them. The bottle was a success, resulting in the customer increasing volumes to over a million bottles to date.Tricorbraun Metallic Bottle

For our client Guess we developed the cap with a special decoration for the Guess Girl fragrance in 30, 50 and 100 ml presentations. The challenge: to ensure that the fabric that had to be used as a decoration was properly assembled to the plastic insert.Cap Development for Guess Girl

We develop large-format packaging for Avon’s personal care products, achieving the delivery of the order effectively and in optimal conditions. We worked with our engineering team to achieve weight optimization, which allowed us to improve the price of the product and reduce material consumption. In parallel, the costs of logistics transport were optimized.1L Bottles in HDPE for Avon

After Avon gave us our first continuing contract, it took us less than two years to become one of their key regional suppliers. To date we have sold over 100 million roll-on bottles to Avon. Amfora’s design and engineering team set out to produce a more attractive, functional and improved appearance solution, but designed to be manufactured at a very competitive price.Avon Roll-on

To achieve the marble finish of the Rose D’Amelie fragrance cap, we performed the two-color injection process on the cap to give that finish without the need for bi-injection.Rose D’amelie L’bel Cap

Responding to a request from our client Natura, we sourced Green HDPE from Brazil to produce Colombia’s first sustainable bottle using resin made from sugar cane.Natura Sustainable Bottle with HDPE bioresin I am greenTMby Braskem

Our client Yanbal wanted to represent the fabric on the female body and the white color to symbolize the purity and elegance of each woman. It was possible to capture the wedding dress design for this fragrance in PP to be able to inject the shapes of the curves of this cap. Additionally, it was painted in a UV matte finish to highlight the polished contrast with the glass bottle.Liberatta Yanbal Fragrance Cap

We developed sustainable packaging for Scandinavia Pharma, a leading customer in the OTC pharmaceutical market. The client needed to change the PVC material of the bottles to a more friendly and sustainable material. Intecplast developed a completely new line of packaging and caps in four different sizes. We work together to define specific material mixes to eliminate the use of PVC resin and achieve the right balance. New product design delivered customer value, increased sales, earned brand recognition, and helped position the product as a premium brand in the OTC market.Schandinavia Pharma Bottle

The challenge: Create a modular lipstick offering style, customization, flexibility and a unique combination of proprietary molds, while minimizing time to market and reducing the need for ongoing mold development. We developed an innovative and disruptive line of modular lipsticks, “ModuLip”, which will allow customers to pick their own customized solution from 64 different alternatives, by combining a standard set of componentsModular Lipsticks With Proprietary Molds

Intecplast developed a luxury PET bottle for Belcorp, taking advantage of creativity and knowledge about this material and various printing and decoration techniques to produce a unique solution. The challenge: take advantage of Intecplast’s know-how in luxury packaging to develop a thick-wall PET bottle in translucent colors, manufactured with multiple decoration techniques (hot stamping, screen printing, labeling). This case was a complete success as it exceeded the sales initially planned, after a successful market launch.Luxury PET Packaging for Belcorp

We accompany the process from start to finish, to guarantee the success of any project. One of our main advantages is the capacity for innovation, we have an R&D team of more than 70 people who support the entire process of customizing products.